Project Description

AGICO TQLZ series vibrating sieve is mainly used in wheat cleaning production to screen out big, medium, small and light impurities. The whole machine adopts special sealing design, avoiding dust problem. This series of cleaning sieve adopts high quality vibration motor and vibration damping rubber spring. The vibrating sieve has many features like low noise, steady operation, large capacity, low energy consumption and good cleaning effect. It also works well with vertical suction separator, so that to further clean the light impurity and dust through air-suction separating. It is the ideal wheat cleaning machine for your grain processing plant.

This vibrating screen is widely used for precleaning and cleaning of wheat milling, flour milling, maize milling, oil processing, animal feed production and other grain separating and cleaning industries. By changing different sieves, this vibrating sieve machine is capable of cleaning various materials such as wheat, corn, ice and oilseeds.

Specifications of vibrating sieve

| Model | Screen cloth size | Capacity (T/Hour) | Power (KW) |

Weight (Kg) |

Size(L×W×H)(mm) | |

| Precleaning | Cleaning | |||||

| TQLZ80×100 | 80×100 | 20 | 6 | 2×0.25 | 360 | 1440×1610×1455 |

| TQLZ100×100 | 100×100 | 30 | 8 | 2×0.25 | 420 | 1640×1610×1455 |

| TQLZ100×150 | 100×150 | 50 | 12 | 2×0.37 | 520 | 2140×1610×1455 |

| TQLZ100×200 | 100×200 | 60 | 16 | 2×0.37 | 540 | 2640×1610×1455 |

| TQLZ150×150 | 150×150 | 75 | 18 | 2×0.55 | 630 | 2140×2160×1455 |

| TQLZ150×200 | 150×200 | 100 | 24 | 2×0.75 | 650 | 2640×2160×1455 |

| TQLZ180×200 | 180×200 | 120 | 26 | 2×1.1 | 1000 | 2700×2480×1830 |

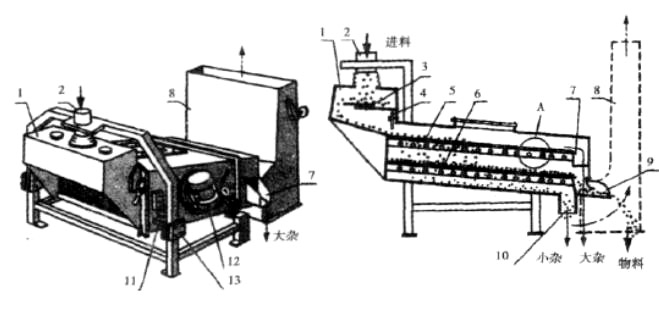

Structure of grain vibrating sieve

The structure of vibrating screen for grain cleaning is as shown in below figure. It is mainly composed of driving devices, feeding device, screen body, fame and other parts. It is generally used with vertical suction separator.

2. Feed Port

3. Adjustable Material Distribution Shedding Plate

4. Uniform Shedding Plate

5. Upper Screen

6. Lower Screen

7. Large Impurity Outlet

8. Air Separation Unit

9. Material Outlet

10. Light Impurity Outlet

11. Hollow Rubber Mat

12. Vibrating Motor

13. Adjustable Support

14. Discharging Choke Plate

- Driving Device: It is driven by a vibrator. There are single-shaft vibrating screen and double-shaft vibrating screen. The amplitude of the sieve can be controlled by adjusting the relative position of the heavy block on motor shaft.

- Screen Body: It is composed of sieve box and its clamp device.

- Frame: The vibrating screen frame can be divided into hanging type and seat-type. Seat-type is featured of simple installation, low installation height and relatively stable performance. The support device is mainly composed of elastic elements which include spiral spring, blade spring and rubber spring.

- Feed Box: It is generally fixed with the screen box and be mounted on the rack through hollow rubber spring. The feed tube is fixed on the frame and connected with the feed box with soft rubber tube.

- Discharge Box: It is fixed on the screen body and vibrates with the screen body.

Types of Vibrating Screen

Screening machine is also named as sieving machine. It has many different types and also has wide application. According to different purpose of use, it can be divided into grain screening machine, mineral screening machine and industrial sieving machine etc. According to different principle of work, it can be divided into eccentric vibrating screen, linear vibrating screen and inertia vibrating screen etc. This TQLZ series sieving machine belongs to wheat cleaning machine. Referring to grain cleaning equipment, there are plane rotary screens, cylinder precleaner and so on.