Project Description

Oil Filtering Press has been around since early 1800s in the United Kingdoms. At that time, oil filter presses functioned in removing seed oils through pressure cells as we still have today. Nowadays, more sophisticated filter press machines are available in the market with various types of standards and configurations. Oil filtering presses are now known with the name of Recessed Chamber Filter Press or Membrane (Diaphragm) filter Press.

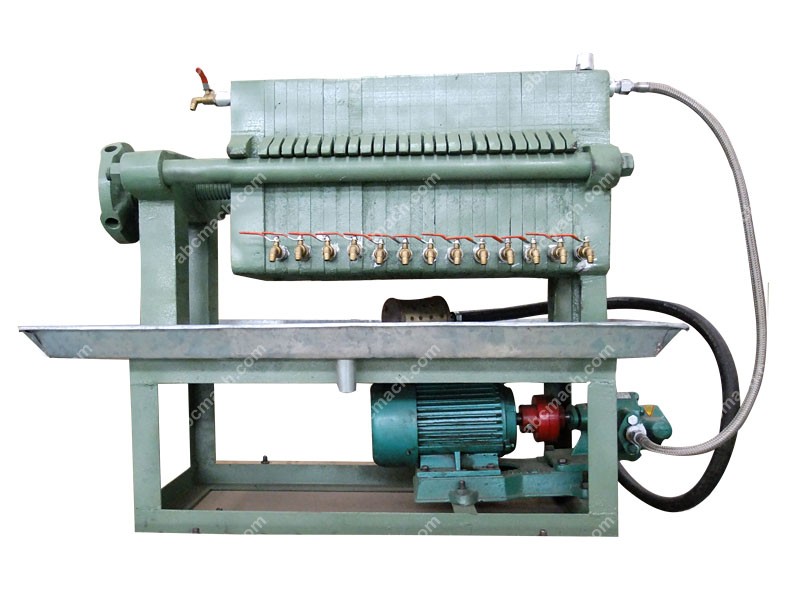

High Quality Small Plate And Frame Filter Press from AGICO

Small plate and frame filter press is also known as plate oil-filter or frame filter. The picture below is a small sized filter press for small scale of filtering crude oil expelled out from screw oil press. This type of plate frame filter can be matched with YZS-68, YZS-80, YZS-95, YZS-100, YZS-120 oil presses for continuous oil processing. This series of filter press is an ideal equipment for mini or small edible oil milling plant or individual workshops, welcome to buy AGICO high quality small plate frame filter press for your small scale oil milling business!

The 6LB series oil filter press is one type of small plate oil-filter which is widely used in small scale oil processing plant or small refining plant for separating solids from crude oil for manufacturing edible or cooking oil.

6LB Plate and Frame Oil Filter Press Parameters

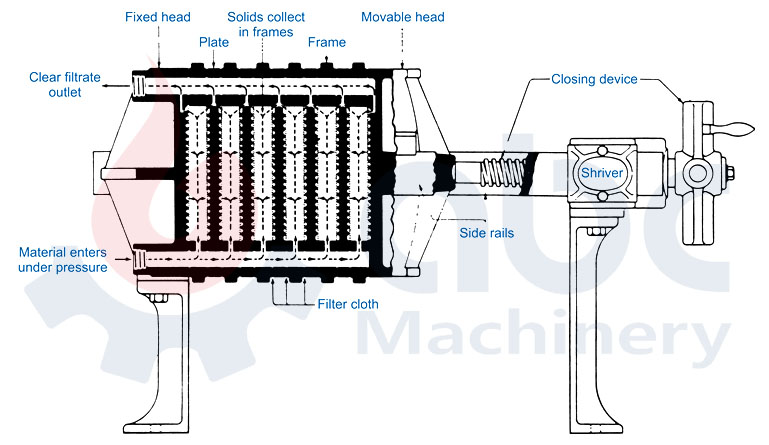

6LB Plate and Frame Oil Filter Press is mainly consists of front stand, rear stand, machine base, pre-filtering clothe, oil pump, tension bolt and filter plate.

| Specification | No.of filter plates | Dimension of filter plate | Working pressure | Productivity | Power | Dimension | Weight |

|---|---|---|---|---|---|---|---|

| 6LB-250 | 13pcs | 250*250mm | 0.3-0.4MPa | 100kg/h | 0.75kw | 780*530*670mm | 155kg |

| 6LB-350 | 25pcs | 350*350mm | 0.3-0.4MPa | 200kg/h | 1.1kw | 1300*750*700mm | 450kg |

AGICO can supply high quality filter presses with maximum filtration efficiency and long service life for different scales of oil production capacities.

Filtering Cloth of Small Oil Filtering Press

This type of small scale oil filtering press is designed with a fine-mesh filtering cloth, making it particularly efficient in edible oil refining process. The filtrating cloth between the filter plates forms many rooms. Under the high pressure effect, the oil goes through the filtrating cloth and then be expelled from the faucet.

Working Principle of Small Oil Filter Press

When the small oil filter press is working, crude oil first enter the filter press chambers through the pump at the speed of 100 psi to 900 psi. The oil fills each plate and frame chamber, then flows through the cloth medium, which is across the drain-field. The pressure generated in the gravity drain field and pressure coming from the pump combines to create a pressure differential, which causes the solid oil cakes to thicken and build up. The filtered oil discharges through the discharge port.

Operation Tips for Small Plate Oil Filter Process

- To prevent leakage of the oil, ensure all the pipe clips are tightened before start the machine.

- Generally, the filtered oil will flow out from the faucet in about 3 minutes after starting the machine. If no oil out, you need to stop the machine immediately and inspect the oil pipe for blockage.