Project Description

This magnetic selector is a kind of small magnetic separation equipment made from AGICO for your grain processing plant. And what’s important is that the magnetic selector doesn’t need any power. It can directly be installed on the entrance of maize milling machines, or be concatenated in the elephant trunks of flour milling plant.

The working process of the magnetic separator is very simple: the machine makes the materials (maize flour, wheat flour…) flow along the circumference evenly in the machine, when the maize flour flows through the magnet, iron impurities will be selected and separate from the flour.

Specification of magnetic selector

| Model | Inlet Diameter(mm) | Capacity(t/h) Wheat | Deironing Efficiency | Magnetic Field Intensity |

|---|---|---|---|---|

| TCXT12 | 120 | 4 | 99.9% | ≥3000GS |

| TCXT15 | 150 | 10 | ||

| TCXT20 | 200 | 20 | ||

| TCXT25 | 250 | 35 | ||

| TCXT30 | 300 | 45 |

Structure And Working Process of Magnetic Selector

Magnetic selector is a small but important part of maize flour milling plant. It is a grain processing equipment which is generally be used with flour mill and maize mill.

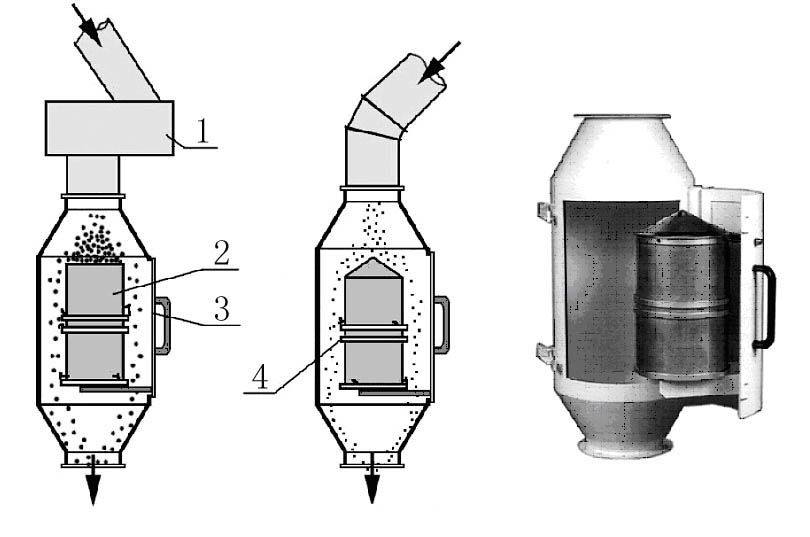

Main Structurer of Magnetic Selector

1. Flexible Coupling

2. Permanent Magnet

3. Inspection Door

4. Impurity Stopper Ring

The structure of magnetic selector as shown in above picture is mainly composed of cylinder, conical magnet and inspection door.

The working process of the magnetic separator is that: the machine makes the materials (maize flour, wheat flour…) flow along the circumference evenly in the machine, when the maize flour flows through the magnet, iron impurities will be selected and separate from the flour. To prevent the absorbed iron impurities be washed away by the flowing flour, there is a stopper ring on the bottom of magnet. This magnetic separator has no automatic impurity discharging function, so the iron impurity on the magnet surface should be cleaned manually and regularly. There is an inspection door to make it convenient to do the cleaning.

In order to ensure the flour material distribute evenly around the magnetic selector, it must be installed vertically. The feeding pipe at the top of the selector should also be vertical, so that to ensure the feeding process vertical and evenly.

Have any questions about magnetic selector for flour milling process? Send us an email and you will get a quick answer in one business day!