Project Description

Industrial high-pressure frame filter or commercial frame filter (plate oil-filter) is specially designed for large scale oil production plant (oil manufacturing and oil refining process). Generally speaking, commercial frame filters are widely used to separate solid and liquid of each kind of suspension liquid. In other professions such as oil dewaxing, coal, petroleum, chemical industry, metallurgy, medicine, light industry, food, environmental protection and spinning, industrial high-pressure frame filter is also widely applied. When the industrial high-pressure frame filter is working, the users can change the filter configuration to get the best using effect according to the specific using requirement.

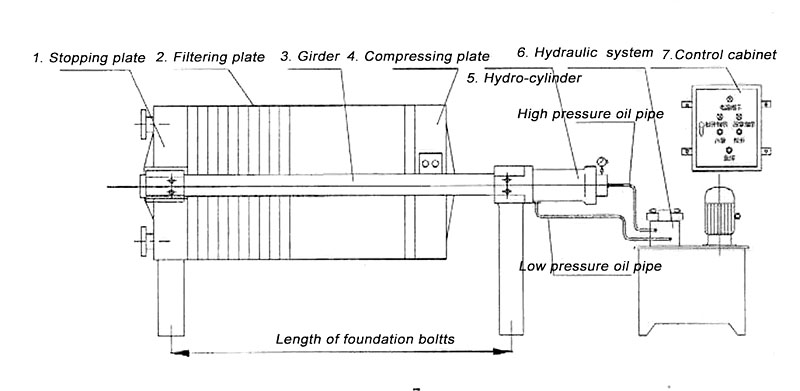

Design drawing of industrial high-pressure frame filter

Design drawing of industrial high-pressure frame filter

The Technical Parameter of the High-pressure Frame Filter

Below is the table that shows the detailed parameters of industrial high-pressure plate and frame oil filter.

| Item | Technical index | Item | Technical index |

|---|---|---|---|

| Filter pressure(Mpa) | ≤1.2 | Filter temperature(℃) | -10 ~ 90 |

| Filter plate outer dimension(mm×mm×mm) | 800×800×60 | Filter cake thickness(mm) | 30 |

| Oil cylinder inside nominal diameter(mm) | 200 | Oil cylinder theoretical route(mm) | 550 |

| The highest pressing working pressure(Mpa) | 25 | The highest protection pressure of the hydraulic pressure(Mpa) | 29 |

| Feeding flange inside nominal diameter | DN65 | Liquid outlet/washing flange inside nominal diameter | DN40 |

| Open flow liquid outlet diameter | Z1/2” | whole machine installed power(Kw) | 1.5 |

Remark:

- When the filter temperature is over 600℃, you should give a clear indication in the contract of purchase.

- When the filter area is 70m2 and 80m2, the oil cylinder theoretical route is 650mm.

Technical Parameter of Industrial High-pressure Frame Filter

| Filter Area ( m2 ) | 60 |

|---|---|

| Filter Board Number | 59 |

| Filter Chamber Volume ( L ) | 960 |

| Mainframe Length( mm ) | 5305 |

| Mainframe Width ( mm ) | 1200 |

| Mainframe Height( mm ) | 1230 |

| Whole Machine Weight ( Kg ) | 4060 |

Remark: The filter board number includes thrust strip and compressing plate.

Features of the High-pressure Frame Filter

- The material of the membrane filter board is the high quality of modified FRPP with special formula. High-temperature healed Diaphragm leaf is processed by the specialized numerical control equipment, so the surface is flat, the finish degree is high, the filter chamber leakproofness is good and the elasticity is strong.

- The FRPP filter board has the advantages of high strength, light weight, corrosion resistance, acid and alkali resistance, Avirulent Insipidity, etc.

- The filter adopts variable cross-section design, in which the filter part structure adopts plum blossom form of Conical dot structure, it can decrease the filter resistance effectively. The filter speed is fast and the filter liquor runner design is reasonable, and the filter liquor flows smoothly.

- The filter mainframe adopts advanced rolled steel to weld, which is to support the filter board filter cake weight and the strong pressure produced during the filtering.

- It takes hydraulic device as the power device of the pressing, loosening the filter board and pull the filter board automatically. The largest pressing intensity of pressure of the oil cylinder is 25MPa, and it adopts electro connecting pressure gauge to realize the automatic pressurizing function between the filter boards.

- The largest pressure it can bear is 0.1MPa of filter pressure, that is to make sure the optimum condition of shaping filter cake to go on the pressure filtration.

- It adopts wall-hanging filter cloth structure, the liquid flows fluently through the filter cloth. The filter cloth surface is smooth and the viscosity degree of the filter cake is less.

- It has many kinds of configurations like PLC autocontrol and relay control, etc. The operation is easy, safe and labor saving. By controlling the operating button on the control panel, you can finish the needed motion. It is equipped with safe devices to guarantee the safety of the operators.