Making briquettes from biomass is a high efficient way to save your energy bill as well as to dispose of biomass waste. As a kind of renewable energy, the biomass briquettes, such as wood briquettes, saw dust briquettes or charcoal briquettes, made by briquetting machine, is widely used both in industry and civil scale for heating as a substitute of conventional fossil fuel – coal in particular. Biomass briquettes can be made from wood, sawdust, crop straw, grass, civil waste and animal waste.

A briquette is manufactured by briquetting machine, also known as briquette maker or briquette press But how does a biomass briquetting machines work? Take making wood briquettes for example, under circumstance of high pressure and temperature, the lignin, which is a kind of polymer in the wood, originally working as a support of wood cell wall, will turn to a sort of plastic matter that stick the briquettes together. That is also why any glue, or binder namely is not necessary in briquetting process, and it is also the reason why the outside of a wood briquette is smooth and shinning.

Raw Materials for Biomass Briquetting Process

- Wood wastes: sawdust, wood chips, wood shavings, logs, branches, logs, etc.

- Agricultural wastes: groundnut shell, paddy straw, sunflower stalk, cotton stalk, robacco waste, coffee husk, mustard stalk, wheat straw, soybean husk, rice husk, etc.

- Other biomass: coconut shell, palm fiber, bamboo waste, etc.

Biomass Briquette Production Lines for Different Scales

Production Processes And Equipments of Briquette Production Line

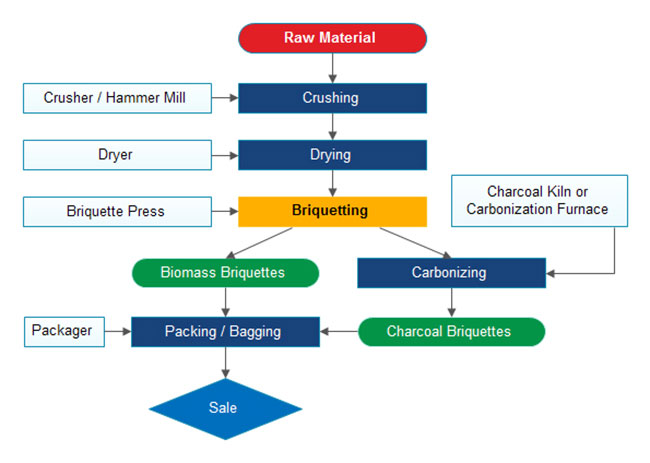

As the above, briquetting is a process that compressing biomass materials into high density solid fuels through high mechanical pressure. Biomass briquettes are generally cylindrical. The cross section can be round, square and hexagon. The biomass briquettes can be used in boiler as a heating source. Besides briquetting machines, we also manufacture auxiliary equipment for turn-key solutions, such as wood chipper, crusher/hammer mill, dryer, briquette machine, cooler, packager and the conveyor connecting each step. If necessary, it needs carbonization device like carbonization furnace to carbonize the wood briquettes into charcoal. Generally speaking, if you want to make a complete briquette production line, you at least need a crushing machine, a drying machine and a carbonization stove as the corollary equipments.

Raw Material—Chipping (optional) → Wood Crushing(optional) → Drying →Briquetting → Biomass Briquettes → carbonizing(optional) → Charcoal Briquettes → Packaging.

Capacity of briquetting plant: 200kg/H ~ 1T/H with screw briquette machine; 500kg/H ~ 5T/H with punching biomass briquette press.

Auxiliary Equipments for Complete Biomass Briquette Production Line

Complete biomass briqutete plant is composed by raw material processing (may include crushser/hammer mill, dryer, etc.), conveying, briquetting (biomass briquette machine), packaging, or even carbonizing (charcoal kiln or carbonization furnace if you want to make charcoal briquettes) processes.

- Hammer mill/crusher (optional): used to pulverize coarse raw materials into required size, generally less than 3mm, so that the crushed materail can meet briquetting requirements.

- Dryer: many briquetting raw materials contain much more water than required (around 15%). Therefore, these raw materials shall be dried till the moisture content reaches required amount.

- Conveyor: used to convey the raw materials into the briquette press evenly.

- Biomass briquette machine: you can choose to use screw briquette press (making hollow wood briquettes or charcoal for sale), or punching briquetting machine (making round solid biomass briquettes or pellets for own use).

- Charcoal kiln (carbonization furnace, optional): if you want to make charcoal briquettes, you need this carbonization furnace. Workers put the biomass briquettes orderly into the kiln (furnace), then seal the kiln, and ignite the waste briquettes to let the integrated biomass briquettes carbonize at high temperature (about 700 degrees Celsius). After 2-3days reaction, the charcoal briquettes are made.

- Packaging machine (optional): the biomass briquettes or charcoal briquettes can be packed for sale or for storage.

Advantages of Building A Biomass Briquette Production Line

Biomass briquettes, known as a compact heating fuel, have several advantages over the traditional fossil fuel:

- Better burning efficiency

Heat value is highly concentrated in briquettes because of its compactness so that more thermal heat can be produced compared with other fuel with the same size. From our years experience as well as feedbacks of the customers, the biomass briquettes, especially wood briquettes are 40% higher in term of burning efficiency. - Tiny size

In AGICO, we are proud of reducing size of the biomass feedstock up to 90%. This results in high bulk density. Unlike raw biomass material whose density is about 60-180kg/m³, the briquettes have a much higher density of around 1200kg/m³. - Smoke and ash free

One of the reasons why you can burn biomass briquettes or wood briquettes in fireplace or stove at home is that they produce no smoke or very subtle ash based on what specific material used for making briquettes. As manufacture technology and relevant fuel energy standardization revamp, to burning biomass fuel: pellets, briquettes and suchlike is getting more and more clean and environmental friendly. - Easy get easy keep

Chances are when you own a saw mill, a furniture factory or a farm, you might have been in trouble dealing with those biomass by-products. One of the easiest way to solve your problem is making them into biomass briquettes. No matter what shapes of briquettes you get: square, hexagon, round, etc. they are always convenient to pack and transport.

Biomass briquettes have more merits other than the above because they are cheap, easy to delivery, recyclable, and so on.

Why Biomass Briquettes Are Being More And More Popular in Our Daily Life?

Biomass briquettes are now more and more popular in our daily life. As an example, briquettes are widely used as a biofuel energy for heating industrial boiler, producing electricity from steam in power plants, BBQ and so on. The biomass briquettes are often carbonized into charcoal for easy storage and transportation as well as high combustion rate. Now that we have realized the importance of development of briquette fuel or pellet fuel, we have to consider one thing that how to make briquettes by the waste materials. The key point is to produce biomass briquette machine with high quality and efficiency. Actually, the briquetting process is a mechanical process which put pressure on the material under a certain temperature in the model. According to different designs of briquette machine, we can divided briquette machines into stamping mechanical briquette machine, screw type briquette machine and hydraulic briquette machine. No matter what kinds and working principles of briquette machines, they can make the lignin content comes out and increase the adhesive ability of particles. Therefore, the small particles combined together stably in the molder. So the lignin content in the biomass material plays an important role during the whole briquetting process. Absolutely, there are still many other factors we have to consider that affect the practical production, like the particle size and moisture content of raw material, temperature control of pelletizing process and the operator’s experience.

How to Choose the Best Briquetting Machines for Your Briquette Production Line?

Given that briquetting industry is an overwhelming trend that will continue being hot and will contribute more and more portion in renewable energy marketing, different designs of briquetting machines are rolled out. By and large, two essential kinds of briquette presses can be observed in the market: stamping type briquette press, screw press briquetting machine, and hydraulic briquetting machine, each type has its unique power driven pattern. It interesting those briquetting machines, especially integrated machinery can both make briquettes and pellets. Scientifically speaking, by looking at its working theory, this dual function machine is just an improved type of stamping briquette press.

From the view of feedstock that a briquette machine is processing, there are charcoal briquettes maker, wood briquettes maker, paper briquettes maker, even metal briquettes maker.