Project Description

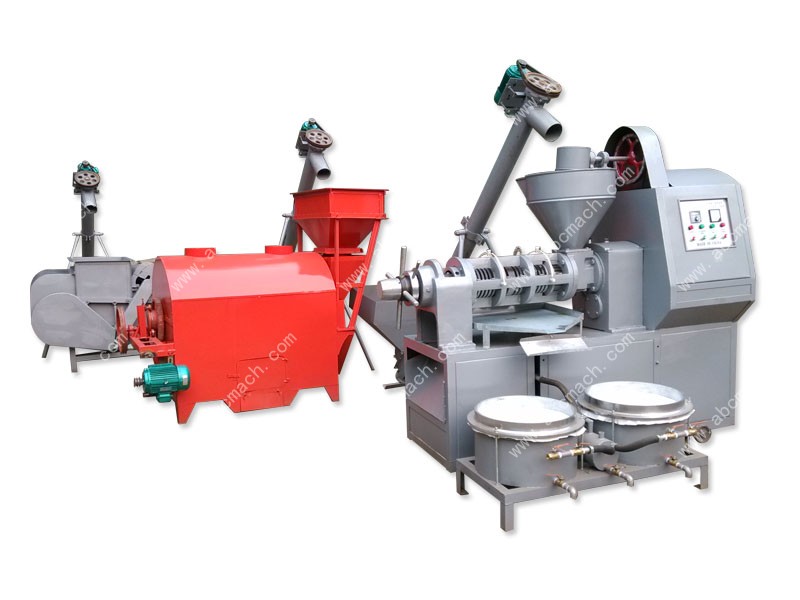

Mini oil milling plant from AGICO is featured of advanced technology, easy installation, efficient oil producing and fine economic benefit. It requires smaller land spacing and little investment compared with large automatic oil milling plant, but mini oil milling plant still contains complete functions that oil milling plant equipped. Compared with single oil press, mini oil processing plant needs less manpower and the feeding is much more stable. Only 2 or 3 worker is enough for a whole mini oil milling plant.

Mini oil milling plant for or called small scale oil milling production assembly unit is a good choice for manufacturing cooking oil from soybean, peanut kernel, sunflower seeds, cotton seeds, sesame seeds, maize germ and many other oil bearing materials.

Main Equipments for Mini Oil Milling Plant

Below are the main machines for the mini oil processing plant. If you are interested in building a mini or small scale of oil making business, our mini oil milling plant is the best choice! Please feel free to send us an inquiry through email if you have any questions about our machines! We are attentive to provide you all-weather 7X24 hours service.

The related machines could be different when pressing different oil-bearing crops. AGICO have a professinal engineering team to make the best tailor-made plan for each of our customer about our mini oil milling plant.

First of all, the oilseeds needed to be cleaned to remove dust, stone, bad ones and other impurities. This cleaning sieve can process various kinds of granular grain materials. It is the most popular cleaning machine for oil production.

This closed drum type rotary roaster is invented by AGICO based on home and abroad advanced technology. It is widely applied to oil mill plant for the cooking of vegetable oil seed. With roasting machine, the oil capacity of the whole plant will be largely improved.

This advance oil press machine combines the function of oil expeller and filtering machine. Compared to traditional expeller, our integrated oil presses are more efficient and need less labor. Moreover, this integrated oil pressing machine is equipped with an electrical control box, so that you can easily control the pressing temperature and make high quality cooking oil product. It is definitely the best choice for small oil processing workshops.Capacity: 2-10 Ton per 24Hour

This is the most common use conveying machinery in oil pressing plant, due to its simple structure and attractive price.

How to Start A Small Oil Mill Plant?

Oil Pressing and Filtering All-in-one Machine for Sale

The center part of entire oil mill plant including small scale production is the oil mill. Oil mill comprises of a worm that is encased in a chamber that is sealed. To enable smooth flow of seeds at the input seeds, oil and refuse at the exit, the chamber has bay and an outlet. The seeds that are precooked are fed via a hopper into the chamber bay. The worm screwing action heads the seeds in the direction of the end that is narrow.

Due to the expanded pressure as the seeds are squeezed to the end that is narrow, oil is discharged. Oil gets away from the chamber through exceptionally minor gaps that are specially built at the end. After it flows via the pipes, the oil is gathered at storage end. After extracting oil, the seed refuse are gathered as oil cakes. This is again an essential commercial item. Most plants calculate their financial practicality by computing the oil cakes sales.

The key part which chooses all the other parameters during the plant set up is the oil mill. This parameters include; Production capacity, size of automation, control over the nature of produce and other commercial viewpoints. Due to many years of research, at Shreeji Oil mills we have composed and built fundamental nature of oil milling machinery considering these contemplations. We have been effective in expanding the yield and keeping up the nature of the extracted oil . This is achieved by exploring more on fine parameters like the outline of the and screw decrease. We have made a progression of items to suit the various needs of the clients. We have accessibility of oil mills that have capacity going from few Kg per hour to a several tones per hour.

There are basically 2 methods of which an Oil mill machine operates. The first one is the mode of cold oil press while the second is the mode of hot oil press. In the mode of cold press, the seed that is incoming is fed directly without preheating. Then again in the mode of hot press the seeds need to undergo the preheating step. The real business contrast is the nature of cake and oil yield. In cold press strategy, the cake created is of more value. The seed yield is compromised by this value. In the mode of hot press, preheating bursts seeds cells, which thus builds the oil yield. In this procedure the cake delivered is of less value when contrasted with cold press. According to the necessity of the commercial sector we have the ability to give either kind of machine of oil mill.

Having an better understanding of how to about starting a small oil mill plant, you are set to go. We are always at your service and willing to help you along the way if you get stuck or whenever you need our assistance.