Project Description

How Much Do You Know About Oilseeds Processing?

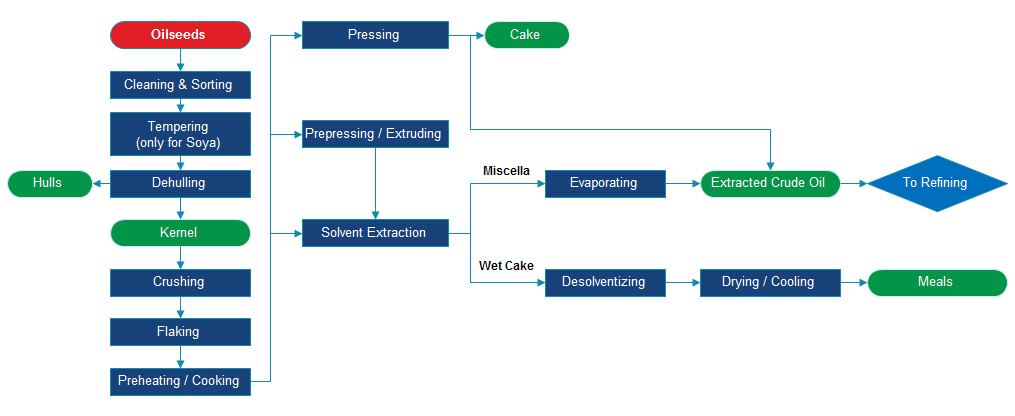

In oil mill industry, oilseeds processing generally refers to the process of extracting oil from oil seeds. In general, oilseed harvesting is the beginning of oilseeds processing, and the oil exaction is the end. The oilseeds pretreatment and prepress plant include cleaning section, breaking section, flaking section, softening section, cooking section and oil pressing section.

Oilseeds Pre-treatment Before Edible Oil Extraction Process

Before edible oil extraction process, the oilseeds need go through pre-treatment processing. As a matter of experience, according to the oil content and physical properties of different kinds of oilseeds, we should apply different oilseed pretreatment processes. So the pre-treatment process varies slightly from one kind of seed to another. But most seed pre-processing processes include cleaning, drying, dehulling, crushing, flaking,cooking and tempering. Below are typical oil seed pre-treatment processes for soybeans, canola seeds and sunflower seeds.

Flow chart of oil pressing process

- Cleaning: Remove impurities such as leaves, sticks, stones, sand, dirt, spoiled seeds and metal contaminants. This processis commonly referred to cleaning and scalping equipment including sieve, destoner, peeling machine, magnetic devices, and beltconveyor etc.

- Dehulling: Most oilseeds need to remove the abrasive shells before oil extracting, since the oil content of shells and hulls is less than 1%. Besides, shelling can not only improve the capacity of oil extraction equipment, increase the efficiency of oil production, but also can reduce wear of oil expeller. Dehuller is commonly used in this process.

- Crushing & Flaking: Most oilseeds require size reduction prior to oil extraction. Crusher and flaker are used in this process. Some small seeds such as corn germ, rapeseed and canola don’t need to be cracked.

- Cooking: Heating the seed is an option, but not necessary. It can increases efficiency of extraction and protein availability.

- Extruding/Puffing (optional):Through extrusion (puffing) by means of expander (extruder), the oilseeds materials will be expanded because of sudden pressure-relief, Meanwhile steam in the material is evaporated all of a sudden, so the material become microporous structure and expanded to irregular particles.

What Can We Do for Your Oil Pressing Line

- Provide turnkey solutions for oilseeds processing projects;

- Responsible for installation and commissioning, staff training.

- Customized each project according to customer’s market, so that to build the most appropriate plan for oil processing production;

- Complete set of after-sales service.

- We can guarantee the low energy consumption in the process of edible oil processing.

AGICO can produce and supply complete set of oil pretreatment machines for you oil milling plant, please don’t hesitate to contact us for more details and quotation of our pretreatment machines!