Project Description

Oil expeller is also called oil screw machine or oil press. In a complete oil milling plant, oil expeller is designed to use physical mechanical pressing method to press oil out from the oil seeds. On the production process of oil expeller, various kinds of raw material are suitable. Such as peanut/groundnut, soybean, sunflower seed, corn germ, palm kernel, copra, mustard, cottonseed, castor, sesame, canola/rapeseed, flax seed, etc. The capacity of single oil expeller machine can range from 10-200TPD.

Technical Parameters of Oil Expeller

| Model | Capacity(t/d) | Power(kw) | Packing size(mm) | Weight(kg) |

|---|---|---|---|---|

| 200A-3 | 7-10 | 18.5 | 2900*1850*3240 | 5000 |

| ZX24-3 | 18-24 | 30+5.5+3 | 2900×1850×3640 | 5500 |

| YZY260 | 40-50 | 75 | 3800*2320*3800 | 9000 |

| ZX283-3 | 40-60 | 55+15 | 3708*1920*3843 | 9380 |

| ZX320-2 | 100-130 | 90+11+5.5 | 4100*2270*3850 | 11500 |

| YZY290 | 150-220 | 135 | 5100*2150*3900 | 14500 |

How to Build A Oil Pressing Plant Oil Expeller

While setting up an oil processing plant, oil seed expeller is a significant component that dictates other parameters such as production capacity, automation scale, and quality of produce among other commercial aspects of production. AGICO has in-depth knowledge, skills and experience with oil presses and have invested heavily in research and development of this component of oil seed processing machine.

As a result of numerous years of research, we has designed and engineered some high quality of oil pressing machinery. Utmost attention has been focused on studying the vital parameters such as the design of the worm and tapering of the screw. This has borne fruits as we has been successful in making machines that ensure increased output as well as high quality of the oil extracted. We has come up with a broad range of expeller oil products that suits the diverse needs of different customers. This includes models that can handle a few kilograms per hour to several tons per hour of oil seeds.

Operation Principle of Oil Expeller

There are two modes of operation for a oil seed expeller, and these are hot oil press mode and cold oil press mode. The significant difference between the two oil presees is that with the cold press mode, the oil seed is fed to the oil machine without preheating whereas with the hot press method the oil seeds have to be preheated. Another significant difference is the yield of oil and quality of the cake. In cold press mode, the cake produced is of high quality and more valuable. This isn’t so with hot press method as the preheating ruptures the seed cells and increases the oil yield but result in a bad quality cake production.

Good Performance of Oil Expellers from AGICO

- Perfect Construction, Simple Control and Durable Service

The oil expeller is characterized by compact construction, high capacity, little floor-space occupation, durable service and easy operation. The amount of feeding, the process of oil yield and the thickness of cake can be readily ascertained at a glance. Their regulations, if necessary, can be satisfactorily made merely by manipulating the feeding regulating lever and the cone setting lever. All the reduction gears operate in oil and the whole surfaces of gear teeth are hardened by heat treatment. The worm shaft (or main shaft) of the oil expeller is made of high-quality alloy steel, thus ensuring long service life. The pressing worms and cage bars in the bar cage are also carburized, therefore, they are wearable and durable.

- Combined Steaming and Roasting

In order to suit the need for heating-up different seeds to varying temperatures for extracting higher quality oil, the oil expeller is provided with meal steaming and roasting equipment kettle which can heat up the above mentioned oil bearing seeds to an optimum temperature before being fed into the pressing cage.

- Automatic and Continuous Operation

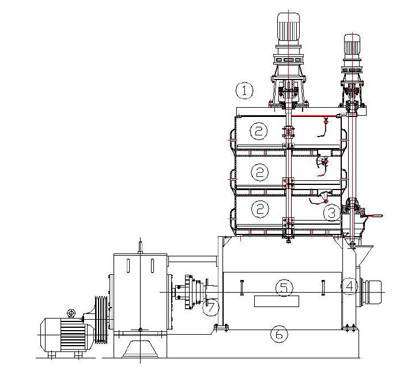

The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heated up and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage, it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressing worms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oil reservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction, beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when once the amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observe the feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirement of supervision and greatly saving labor.

Features of Oil Expeller from AGICO:

- Large processing capacity

- Combined Steaming & Cooking

- Lower energy consumption

- Automatic and Continuous Operation

- Flexible production

- Higher quality oil and cake & Steady oil yield

- Perfect Construction, Simple Control and Durable service